PHARMACEUTICAL FILL FINISH & OSD

CLEAN AIR INNOVATION TO GUARD AGAINST DOWNTIME

Facilities for pharmaceutical fill finish — the process of creating drugs with chemicals — demand a strictly controlled environment at every stage of research, development and manufacturing. Precise air filtration is crucial in the cleanroom and beyond. That’s why the pharmaceutical industry relies on AAF. We design advanced air filtration systems that minimize the threat of airborne contaminants while also helping manage costs and achieve sustainability goals. We build rugged, reliable equipment needed to mitigate costly delays and patient risk. There’s simply too much at stake to deliver anything less.

- Click an area name from the menu below.

- Click the hotspots to explore filtration solutions.

INDUSTRY-LEADING PRODUCTS

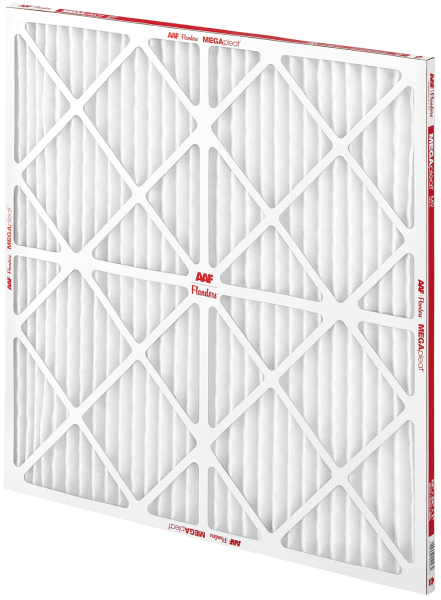

MEGApleat® M9

The MEGApleat M9 filter is the longest-lasting and strongest pleated prefilter available. Its service life is 3 to 4 times longer than standard pleated filters. The low initial resistance and high dust-holding capacity help reduce energy use to lower operating costs.

HEATMOS®

The HEATMOS high-temperature HEPA filter is designed to maximize productivity and minimize downtime. It offers exceptional ramp speed and H14 performance to meet the requirements of EN1822, even after repeated heat cycling.

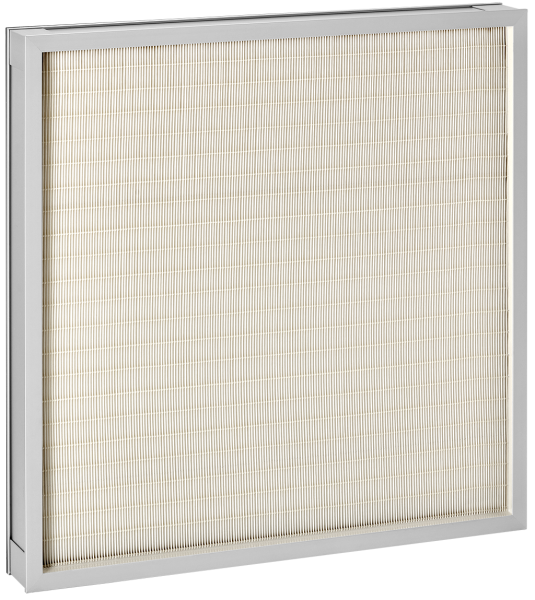

MEGAcel® II

The MEGAcel II mini-pleat eFRM media HEPA filter is designed to help increase cleanroom uptime and reduce risks associated with pharmaceutical manufacturing. In addition to its durability, high particulate filtration efficiency and lowest pressure drop, the MEGAcel II eFRM is the industry’s first and only eFRM media compatible with polyalphaolefin (PAO) for HVAC validation.

MEGAcel® I

The MEGAcel I eFRM is our highest performing HEPA filter. It’s designed to be an industry leader, made with AAF’s expanded FluoroResin Membrane (eFRM) media and innovative tapered aluminum separator design. These filters help optimize system efficiency and integrity while minimizing operational expenses in the most demanding applications.

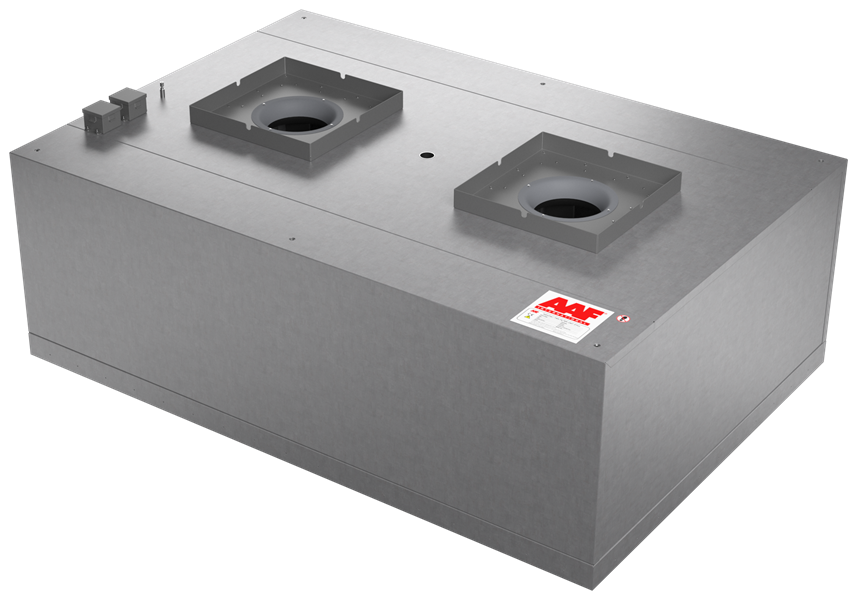

AstroClean™

AAF offers unidirectional airflow modules designed for cleanliness levels of ISO Class 5 or above. These modules supply clean air to processes and equipment for freeze dryers, vial filling systems and cell culturing. A wide range of options, sizes and configurations are available to create a solution for virtually any facility.

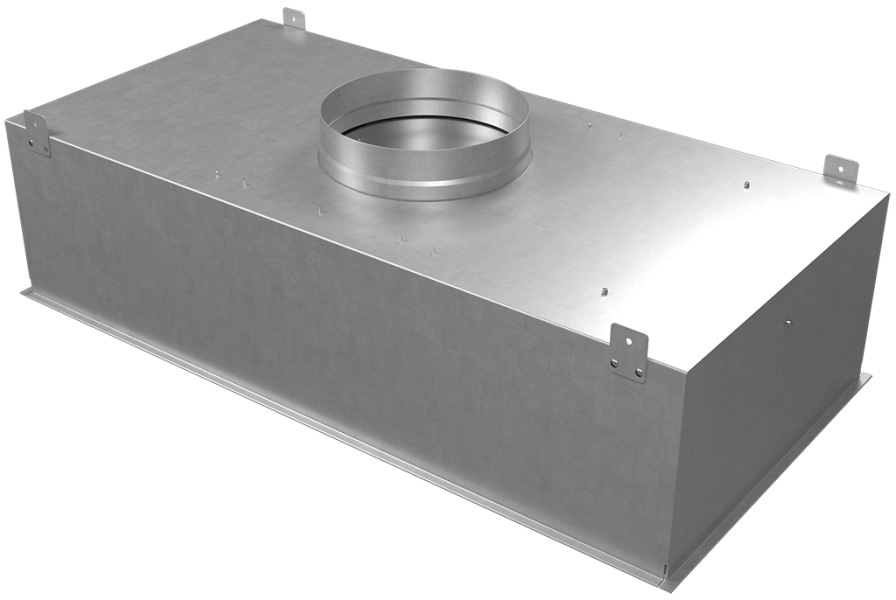

AstroHood® S-II

The AstroHood S-II is a welded terminal filter supply hood with options and features to meet stringent cleanroom requirements. Sturdy and reliable, it can be installed in many different ceiling types and is suitable for applications where regular performance validation is required.

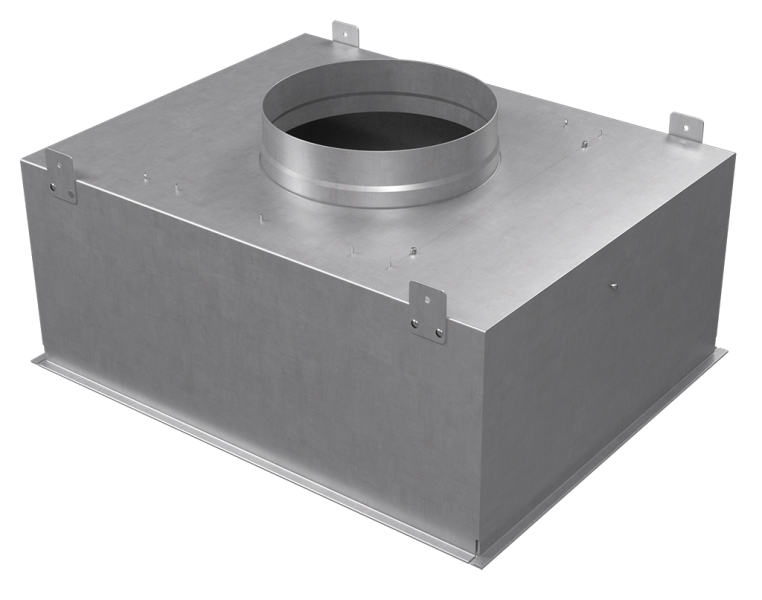

AstroHood® S-I

The AstroHood S-I is a fully welded terminal filter supply hood for cleanrooms that offers the lowest operating cost of any of our units. Its zero-pressure boundary penetrations help reduce risk and reduce energy use.

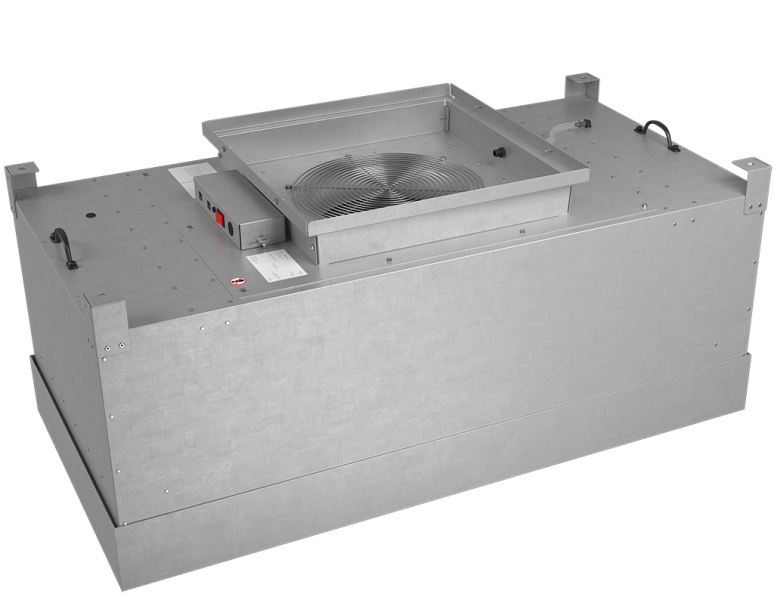

AstroFan™ EC FFU

The AstroFan EC FFU is whisper-quiet and can be networked and controlled for increased ease and efficiency. Industry-leading low filter resistance and our rigorous in-house testing ensure system integrity and economy.

AstroSafe® V

The AstroSafe V addresses the pharmaceutical industry’s continuous concerns for safety. These innovative types of containment housings may also be used in other applications where the containment of dangerous or potent toxic compounds is prevalent and the ease of side servicing from within the conditioned space is a benefit.

INDUSTRY-LEADING BENEFITS

HELPS PROTECT AGAINST FILTER LEAKS AND DAMAGE THAT CAN LEAD TO DOWNTIME

SUPPORTS SUSTAINABILITY GOALS WITH ENERGY-EFFICIENT DESIGNS

Helps protect against filter leaks and damage that can lead to downtime

Standard glass HEPA filters are common, but they weren’t originally designed with modern cleanrooms in mind. Today, any filter leaks or failure can be catastrophic, so AAF provides filtration through media developed to reduce your concerns over validation. The MEGAcel I eFRM was designed to offer peace of mind in critical spaces and for ISO-classified areas, the MEGAcel II eFRM is hydrophobic and rugged to help protect against damage during handling and the resulting downtime.

Supports sustainability goals with energy-efficient designs

Pharmaceutical fill finish cleanrooms demand much more energy than other commercial facilities. That’s why AAF designs solutions that optimize efficiency at every stage of an air filtration system. The robust MEGApleat M9 filter combined with the VariCel VXL filter offers high dust-holding capacity and energy efficiency to help businesses meet their sustainability goals, and the HEATMOS HEPA filter is classified for H14 efficiency, helping solve heat efficiency drops in cost-effective fashion.

TRUSTED BY

LET'S CHAT!

Learn how AAF can make a difference.