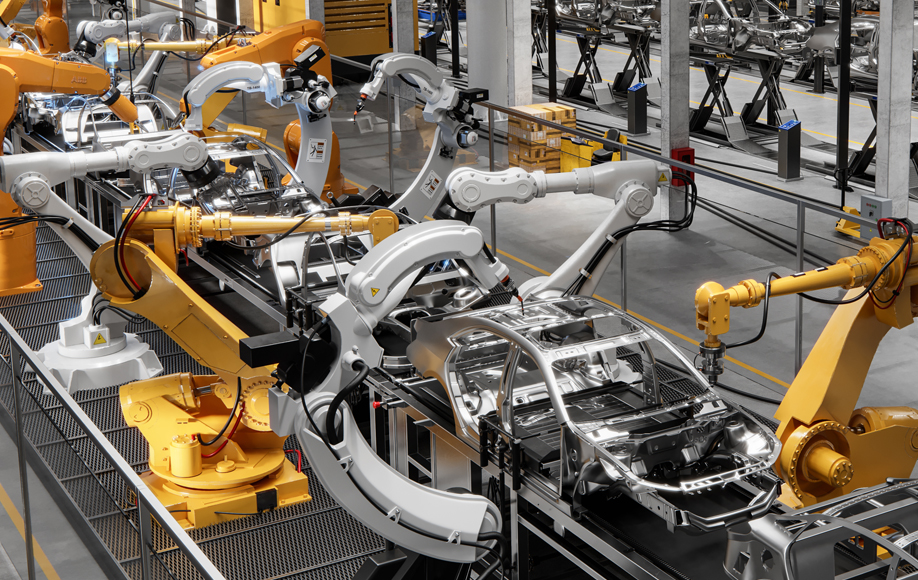

AUTOMOTIVE

COST-EFFECTIVE CLEAN AIR TO HELP KEEP PRODUCTION RUNNING

Filtered air in automotive manufacturing plants is a necessity. Contaminants are produced at nearly every stage of the manufacturing process. AAF’s air filtration solutions can help protect employees and equipment by reducing many harmful gases and particulates — including those generated by processes such as welding, grinding and painting. AAF is an experienced partner in providing the energy-efficient clean air systems needed to help create a safe, productive work environment and decrease chances of product defects.

Filtered air in automotive manufacturing plants is a necessity. Contaminants are produced at nearly every stage of the manufacturing process. AAF’s air filtration solutions can help protect employees and equipment by reducing many harmful gases and particulates — including those generated by processes such as welding, grinding and painting. AAF is an experienced partner in providing the energy-efficient clean air systems needed to help create a safe, productive work environment and decrease chances of product defects.

INDUSTRY-LEADING PRODUCTS

Sensor360®

The Sensor360 technology platform demonstrates the effectiveness of a building’s filtration system by monitoring particulate levels. The sensors measure particulate concentration in both unfiltered air and indoor air, and communicate values to a mobile/ tablet/ computer app. Facility managers receive instant notifications with actionable insights. This enables them to optimize air filtration, identify issues early and take targeted action to improve indoor air quality.

VariCel® VXL

The VariCel VXL is the highest-performing and longest-lasting box filter in the HVAC filter line. This filter was developed to offer the lowest cost of ownership thanks to its unique combination of features. The V-bank design and dual-density fiberglass media provide excellent performance under difficult operating conditions.

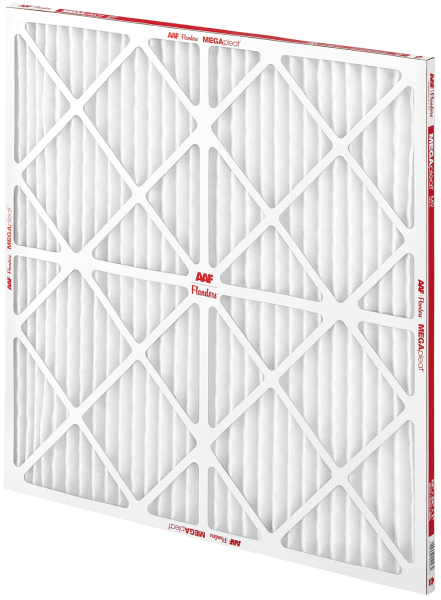

MEGApleat® M9

The MEGApleat M9 filter is the longest-lasting and strongest pleated prefilter available. Its service life is 3 to 4 times longer than standard pleated filters. The low initial resistance and high dust-holding capacity help reduce energy use to lower operating costs.

SuperFlow® Supreme

SureFlow Supreme diffusion media is specifically designed for use as the final filter in the supply air system of low velocity paint spray booths. This synthetic media forms a highly effective final protective barrier against particles, even at temperatures up to 212˚F (100°C).

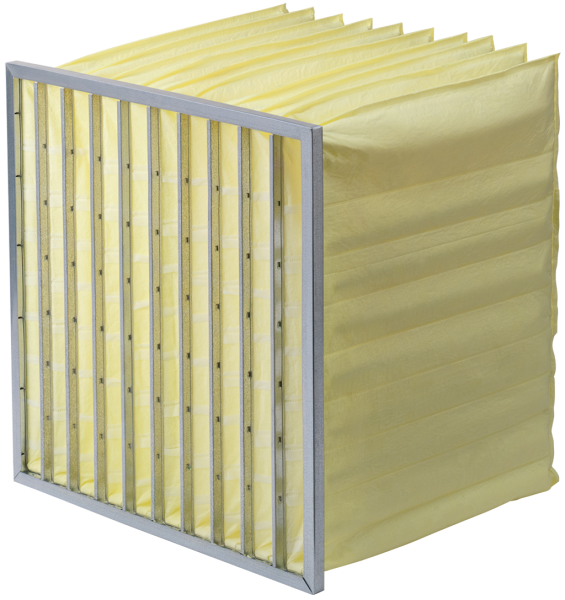

DriPak® GX

The DriPak GX bag filter was designed to maximize filter life and reduce energy use. It uses microfine fiberglass media in a proprietary tapered-pocket design. Choose it for pre- or final filtration in central air handling systems as well as prefiltration for cleanrooms.

HEATMOS®

The HEATMOS high-temperature HEPA filter is designed to maximize productivity and minimize downtime. It offers exceptional ramp speed and H14 performance to meet the requirements of EN1822, even after repeated heat cycling.

MEGAcel® I

The MEGAcel I eFRM is our highest performing HEPA filter. It’s designed to be an industry leader, made with AAF’s expanded FluoroResin Membrane (eFRM) media and innovative tapered aluminum separator design. These filters help optimize system efficiency and integrity while minimizing operational expenses in the most demanding applications.

SAAF™ Cassette MD

The SAAF Cassette MD was designed for superior energy efficiency. It has an energy-efficient design that can improve fit and sealing integrity over existing cassette holding systems.

INDUSTRY-LEADING BENEFITS

Helps control energy costs

Taking control over energy usage can make an impact on profitability in automotive manufacturing. That’s why AAF develops clean air solutions with energy economy in mind. The innovative pocket design of the DriPak GX filter helps optimize air distribution to achieve better efficiency than fiberglass bag filters. The MEGAcel l eFRM filtration is designed to reduce initial resistance over standard glass media, and the VariCel VXL is a high-efficiency 8-panel filter with a low-pressure drop to use less energy.

Reduces airborne and gaseous contaminants

A safe working environment requires effective air filtration and dust collection solutions. AAF provides filtration solutions designed to reduce hazardous contaminants generated during the automotive manufacturing process. MEGAcel l offers HEPA filtration along with peace of mind, thanks to a durable polymer-based media with a high tensile strength to help reduce damage. For gas filtration applications, heavy-duty SAAF Cassettes feature plastic rivets at multiple points to help protect against leaks during normal usage. The design eliminates stickers and labels that could lead to failure.

TRUSTED BY

LET'S CHAT!

Learn how AAF can make a difference.